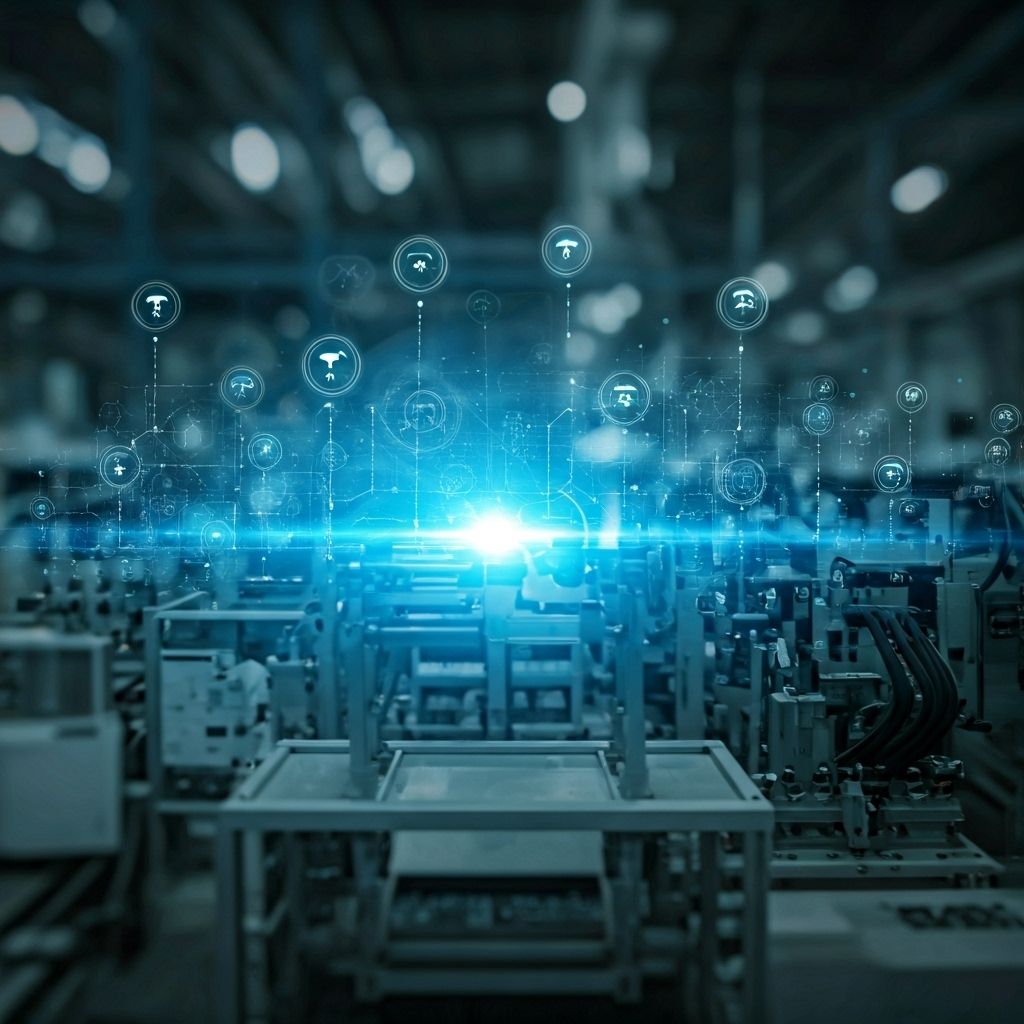

The integration of IoT sensors is reshaping the manufacturing sector by enabling real-time data collection, predictive analytics, and automation. Smart factories are no longer a futuristic vision—they are a present reality driving unprecedented efficiency gains.

Key Benefits of IoT Sensors

- Real-Time Monitoring: Immediate insights into equipment health and production flow.

- Predictive Maintenance: Detecting potential failures before they occur, minimizing downtime.

- Resource Optimization: Efficient energy usage and material management reduce waste.

- Enhanced Safety: Environmental sensors ensure workplace compliance and worker well-being.

Practical Applications in Manufacturing

From assembly lines to supply chain logistics, IoT sensors are transforming operations across the industry. Here are a few notable examples:

- Quality Control: Vision and vibration sensors detect defects instantly.

- Inventory Tracking: RFID and smart tags automate stock management.

- Energy Management: Smart meters optimize power consumption in real time.

- Robotics Integration: Collaborative robots use sensor data for precision tasks.

Challenges and Considerations

While the potential of IoT sensors is massive, manufacturers must address several challenges:

- Data Security: Protecting sensitive production data from cyber threats.

- Scalability: Ensuring networks handle increasing sensor deployments.

- Integration: Seamlessly connecting legacy systems with modern IoT solutions.

- Costs: Initial investments in hardware and infrastructure can be high.

Conclusion

IoT sensors are a cornerstone of smart manufacturing, enabling data-driven decisions that improve productivity, reduce downtime, and ensure higher quality outputs. As sensor technology advances, companies that embrace these solutions will lead the way in Industry 4.0.