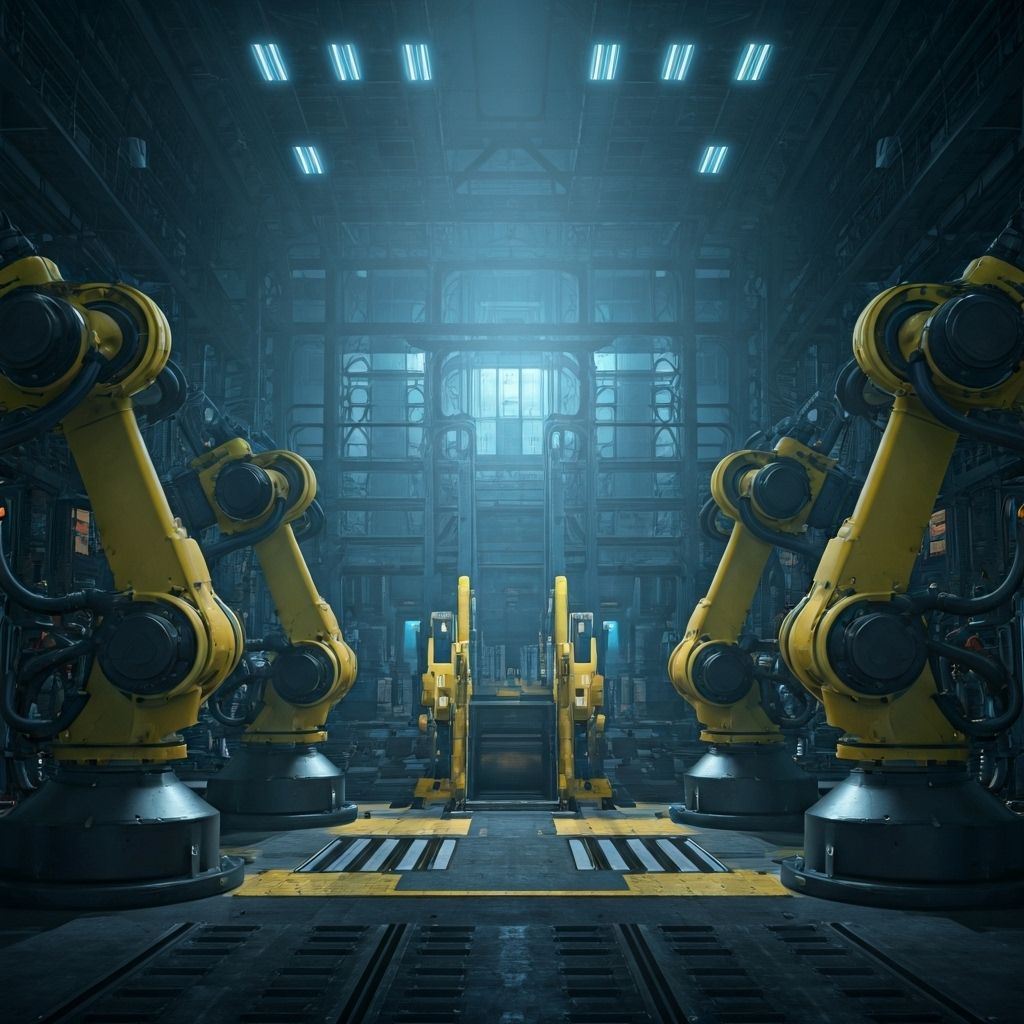

Introduction: The New Era of Automation

The landscape of manufacturing and logistics is undergoing a profound transformation, driven by the rapid evolution of industrial robotics . In 2025 and the years following, we're moving beyond simple, repetitive automation. Advanced AI and IoT integrations are redefining how machines and humans collaborate on complex tasks, signaling a new era for industrial robotics .

This shift focuses not just on speed, but on flexibility, safety, and intelligence. The future of industrial robotics promises leaner operations, enhanced precision, and the opening of new operational possibilities across numerous sectors.

Key Trend 1: AI Integration & Machine Learning

Robots are no longer static programs; they are dynamic learners. AI Integration is the most critical element shaping the future of industrial robotics . By leveraging machine learning, robots can now:

- Optimize Workflows: Real-time data processing allows robots to autonomously adjust their movements and speed, significantly boosting production efficiency.

- Predictive Maintenance: AI analyzes sensor data to anticipate equipment failure, drastically reducing downtime—a crucial development for modern smart factories .

- Advanced Vision: Robots equipped with sophisticated vision systems can perform complex inspection tasks with human-level (or better) accuracy.

Further Reading: For a deeper understanding of the underlying technology, check out our post on AI in Manufacturing to see how these systems are deployed.

Key Trend 2: The Rise of Collaborative Robots (Cobots)

Collaborative Robots , or Cobots , are human-friendly robots designed specifically to assist workers safely. This represents a paradigm shift from traditional industrial robotics , where human-robot separation was mandatory.

Cobots use advanced sensors and speed-monitoring systems to operate safely alongside people, making automation accessible to small and medium-sized enterprises (SMEs). This trend is crucial as it addresses the growing demand for flexible and adaptable production lines.

According to a recent report by the International Federation of Robotics (IFR), the Cobot segment is projected to experience double-digit growth, highlighting its importance in the immediate future of industrial robotics .

Key Trend 3: Smart Factories and the IoT Ecosystem

The complete integration of industrial robotics into the Internet of Things (IoT) ecosystem defines the Smart Factory . These factories are fully automated, utilizing interconnected devices and predictive analytics to achieve unprecedented levels of efficiency.

In a Smart Factory, every machine, from the smallest sensor to the largest industrial robot , communicates in real-time. This connectivity allows for immediate adjustments to supply chain disruptions, changing customer demands, and resource management, solidifying the role of autonomous automation.

People Also Ask (PAA): Common Questions on Robotics

Conclusion: The Road Ahead

The future of industrial robotics promises smarter, safer, and more efficient production systems. The convergence of AI, IoT, and robotics will define the next decade of global manufacturing — empowering industries to achieve precision, sustainability, and scalability like never before.